Transformers are one of the most critical components in electrical transmission and distribution networks. The impacts of transformer failure can be catastrophic and could lead to loss of revenue, disruption, forced outages, costly repair, and serious injuries. Therefore, it is imperative to provide reliable and efficient transformers for the continued stability of the power network.

Extensive innovation and development efforts in transformer design have resulted in an alternative to dry type – GSM™ Transformers.

GSM™ transformers exceed conventional transformers in safety, installation footprint, environmental benefits, reliability, and return on investment. The GSM™ transformers are Factory Mutual (FM) approved as per approval standard FM 3990, passing a stringent testing process to ensure the equipment adheres to the highest level of standards in quality, performance, and technical integrity. The rigorous certification & testing process means that less than ten companies in the world are certified to manufacture transformers that comply with AS/NZS 60076 and FM Approval Standard 3990 [1].

Better Safety and classed as Fire Protection Equipment

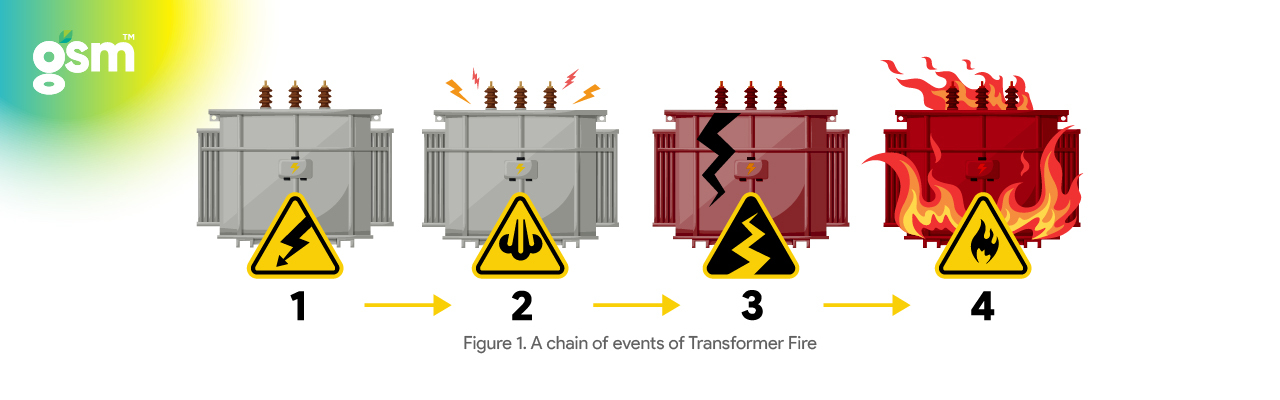

GSM™ transformers are the safest in its class available in the industry. As part of the certification process, a reference design unit undergoes destructive testing such as pressure withstand, fire suppression capabilities, and physical performance. The pass criteria are set out in Approvals Standard FM 3990. The standard aims to eliminate the explosion & fire risk through mitigation strategies. The chain of events of transformer fire or explosion is demonstrated below:

Figure 1. A chain of events of Transformer Fire

Event 1: A fault event has occurred.

Event 2: Rapid pressure increase due to arcing producing flammable gasses.

Event 3: Transformer tank ruptures due to internal pressure

Event 4: High-temperature liquid and pressurized gasses escape causing fire-inducing explosions.

Risk elimination is the most preferred and at the top of the risk reduction hierarchy, and which FM 3990 standard achieves this by requiring manufacturers to implement the following risk reduction strategy.

Risk Mitigating 1: Limit low and high energy faults by protection relay & devices.

Risk Mitigating 2: Transformer to withstand higher than normal pressures without rupture.

Risk Mitigating 3: Rapid and high-volume pressure relief to eliminate explosions.

Risk Mitigating 4: High fire point insulating liquid to avoid consequential fires.

The purpose of each mitigating action is to interrupt the chain of events and consequently avoid catastrophic failure. The differences in tank pressure withstand, relief flow rates and fluid fire point requirements between a GSM™ and conventional transformer, in Table 1.

Reduced Clearance & Installation Footprint

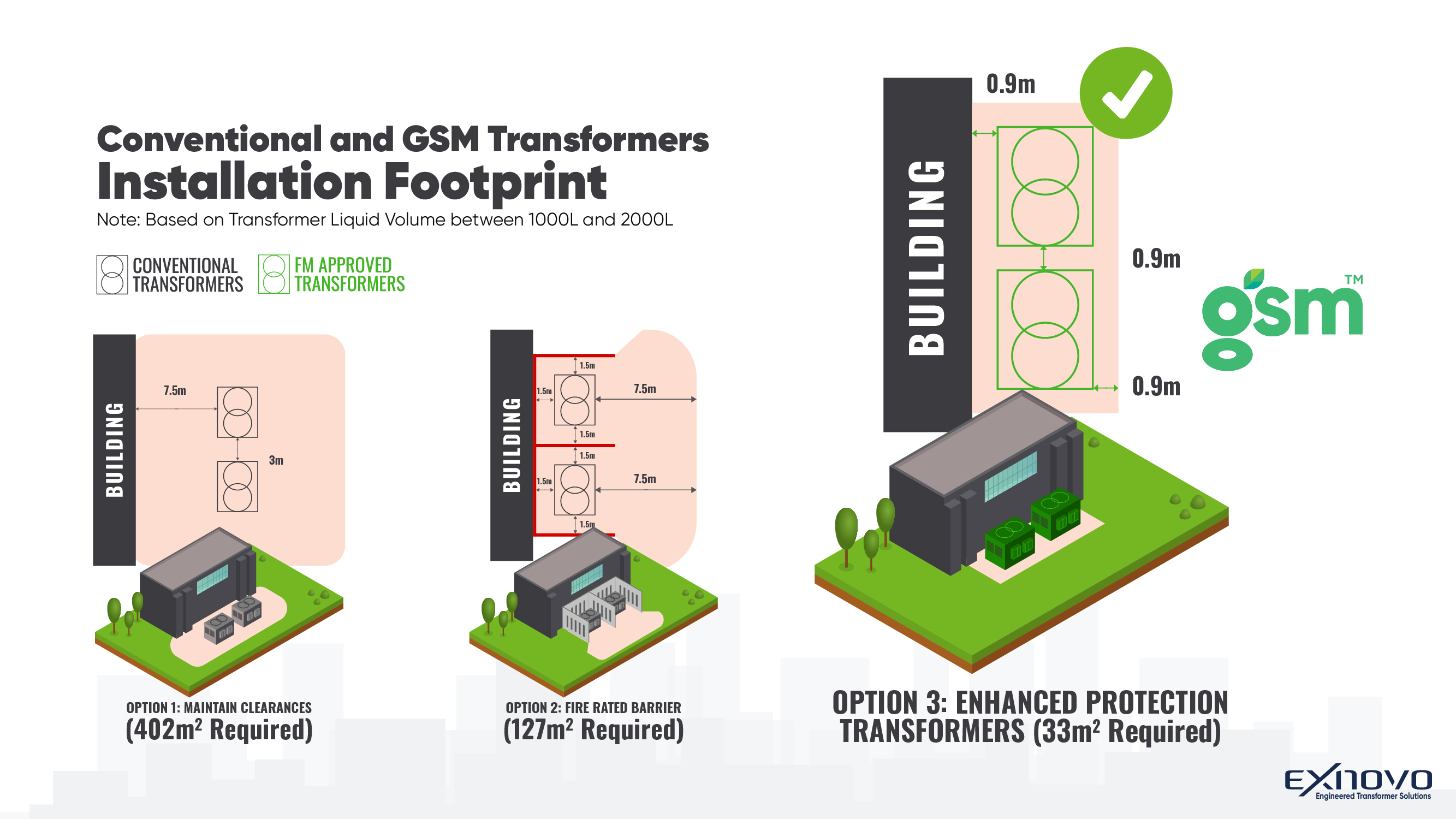

Australian Standard AS2067, titled: “Substation and high voltage installation exceeding 1kV a.c” provides common rules for the design of power installation and clearance distance required for both indoor and outdoor transformer installation. GSM™ transformers are certified as less combustible liquid-insulated transformers (K) with enhanced protection. This allows GSM™ to be installed 0.9m from other transformers or building surfaces. In comparison, a dry type and conventional transformer require clearance from the building of 1.5m and 7.5m, respectively.

The figure below further illustrates the reduction in footprint in an outdoor use case.

Figure 2. Conventional and GSM™ Transformers Installation Footprint

Improved Environmental Sustainability

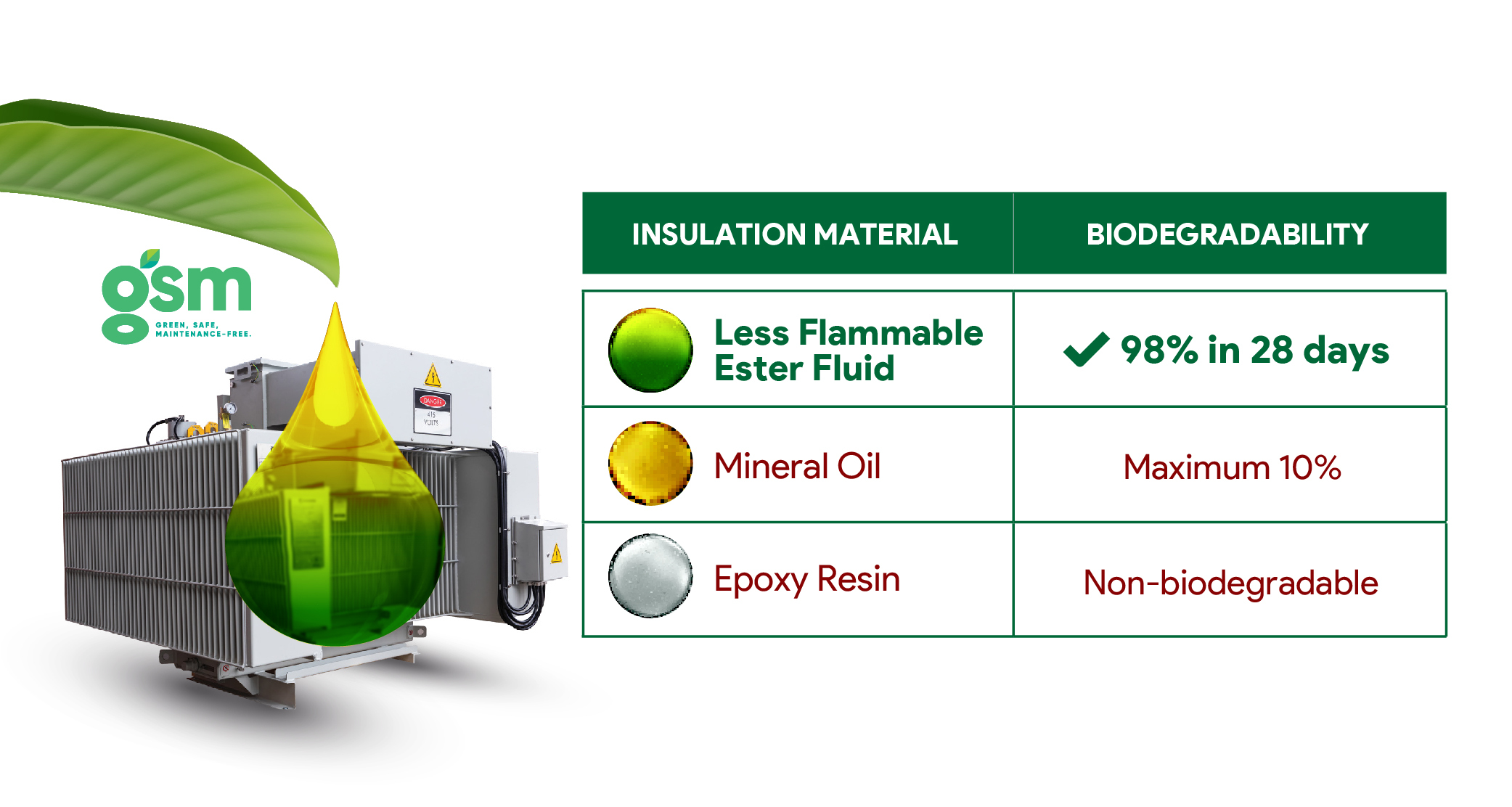

For more than 100 years, mineral oil has been predominantly used as the insulation liquid in the transformer industry [4]. With the concern of environmental impact and fire-safety, a trend in recent years has shifted the focus to ester fluid as an alternative to mineral oil. Additionally, natural ester fluids are readily biodegradable and have a higher flash point as compared to mineral oil.

The GSM™ transformer uses a less-flammable fluid that is non-hazardous to the environment and can readily be biodegradable within 28 days. Furthermore, the self-extinguishing properties of the less flammable fluid can greatly reduce the environmental impact if spillage occurs and mitigate fire risks.

The less-flammable fluid used in GSM™ transformers ensures the equipment meets the highest standard of safety, in which it has a flash point of 327°C while conventional mineral oil has 160°C respectively.

The use of GSM™ transformers in various applications can also help industries to demonstrate steps toward positive corporate sustainability.

Reliable Performance

Every GSM™ transformer undergoes an in-depth performance test that goes beyond the Australian Standard. Due to the manufacturing technique and enhanced protection of GSM™ transformer, the equipment can last more than 30 years under normal use and operation, without requiring any servicing or maintenance.

As part of the FM Approvals quality assurance program, the manufacturing facility of GSM™ transformers is audited every three months to maintain certification and compliance. This is to ensure the GSM™ transformers remain consistent with what was tested and FM-approved.

Higher Return on Investment

Transitioning to less-flammable GSM™ transformers can significantly minimise fire risk and reduce the insurance premium. A recent FM Global webcast reported that clients experienced over 500 transformer failures totaling more than $US900 million ($AUD1.29billion) in the last 10 years. This is equating to an annual average loss cost of over $US90 million.

The same study also revealed a case study of an industrial facility where the walls and roof are constructed with polystyrene sandwich panels. There were three mineral oil-filled kiosk transformers situated approximately 1.5m from the building. Each transformer contains 500L of mineral oil. In the event of a transformer fire, the estimated loss of the factory and production totaled $US200 million. In addition, it will take at least one year to rebuild the factory. One solution was to upgrade the existing equipment with FM-approved transformers such as GSM™, which resulted in the estimated loss reduction from $US200 million to $US100,000 [5].

Our team has an in-depth understanding of the Australian Standard and industry and has shown that the GSM™ transformers can unlock benefits for asset owners. The product and design are regularly reviewed by a team of transformer experts to ensure adherence to local standards and regulations. GSM™ transformers have been used and installed in some of the harshest conditions including Australian mine sites.

For further information, please contact EXNOVO at +61 (8) 6102 2814 or email us at contactus@xnv.com.au or visit us at xnv.com.au.

Reference

[1] “Less or Non-Flammable Liquid Insulated Transformers”, Approval Guide, 2020. [Online]. Available: https://www.approvalguide.com/....

[2] “Approval Standard for Less or Nonflammable Liquid-Insulated Transformers: Class Number 3990”, FM Approvals, 2018.

[3] “Substations and high voltage installations exceeding 1 kV a.c.”, Standards Australia, 2016. [Online]. Available: https://www.standards.org.au/s...–2067-colon-2016.

[4] R. Liu and C. Tornkvist, “Ester fluids as alternative for mineral oil: The difference in streamer velocity and LI breakdown voltage”, 2009 IEEE Conference on Electrical Insulation and Dielectric Phenomena, 2009. Available: 10.1109/ceidp.2009.5377896

[5]”Innovating in the Substation to Reduce Risk”, MIDEL, 2020. [Online]. Available: https://www.midel.com/innovati....