Transformers are among the most critical components in an electrical and distribution network. Extensive innovation and development efforts in transformer design have resulted in a greener alternative – GSM™ transformer with Enhanced Protection.

This article explores the key differences and benefits of various scenarios with fire risk mitigation as a key consideration.

SAFETY MEASURES FOR TRANSFORMERS

All substation and high voltage installations in Australia must comply with the Australian Standards, specifically AS2067: (Substations and high voltage installations exceeding 1 kV). There are many factors that influence its design, such as operating voltage and capacity. Many designers in the industry would agree that the most critical consideration to make is safety.

The transformer is a critical equipment in any substation installation, and due to a large amount of energy, fire is a real risk. The Australian Standard defines the fire risk zones and safety measures required around the transformer compound. Fire resistance level (FRL) walls and separation distance (clearance) are two mitigation strategies commonly utilised in the industry. The Australian Standard also provides the minimum separation distance required between transformers and other buildings or equipment. The separation distance is affected by the following factors:

- Installation location – indoor or outdoor,

- Volume of transformer insulating liquid,

- Fire Resistance Level of building, and

- Type of transformer.

OUTDOOR INSTALLATION

In an outdoor transformer installation, the fire risk zone is measured from the transformer bund perimeter and extends to the edge of the separation distance, as shown in Figure 1. The separation distance is determined by the volume of insulating liquid, which is proportional to the rated capacity of the transformer. An approximation of insulating liquid volume to transformer capacity ratio is 700L per 1000kVA, for a typical hermetically sealed type of transformer.

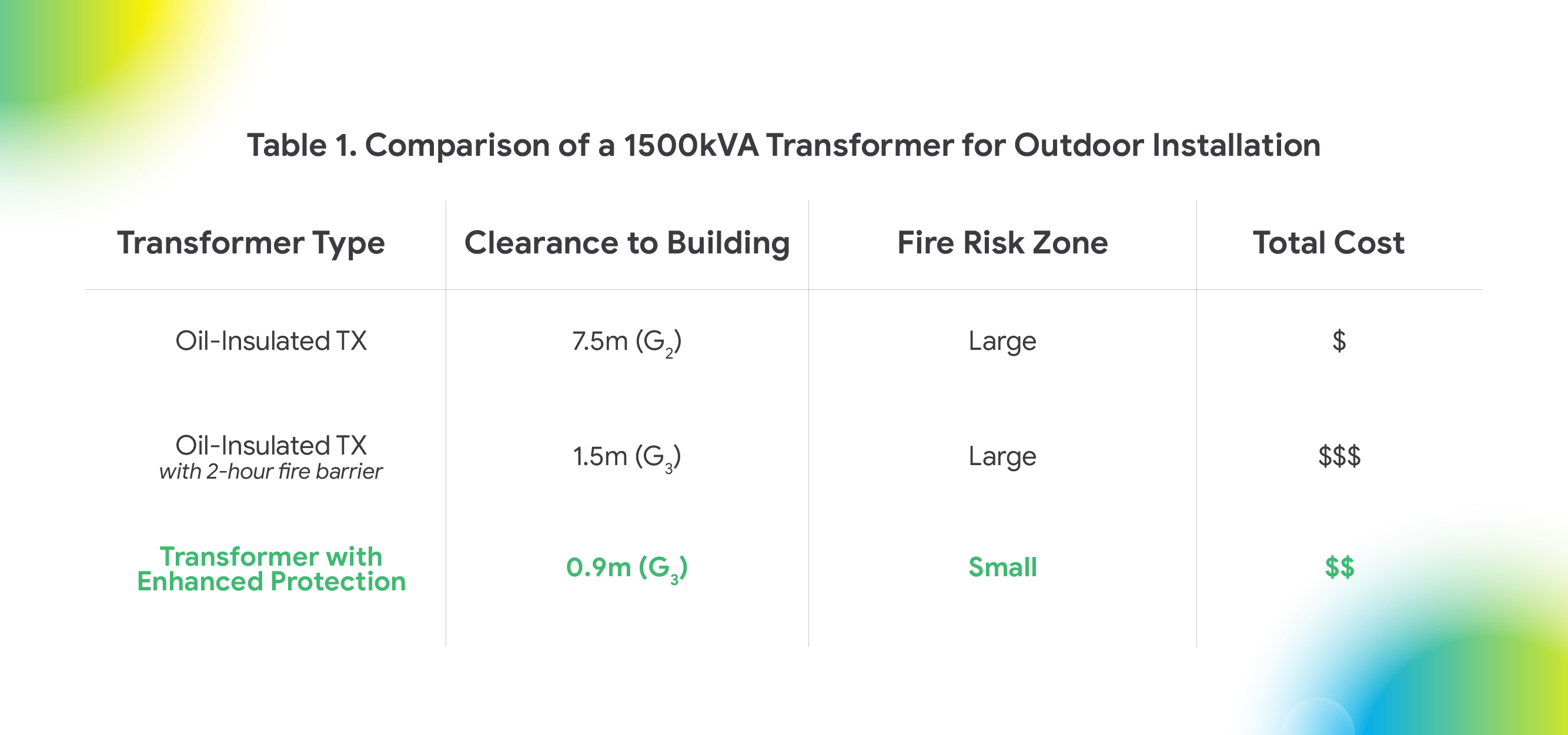

The clearance for an outdoor transformer is defined in AS2067. For instance, a typical installation arrangement of 1500kVA ONAN transformer will have an oil volume between 1000L and 2000L. The Australian Standard states that its minimum separation distance (G2) is 7.5 meters around the compound, denoted as fire risk zone in Figure 1. There are a few design scenarios available, as outlined below.

Scenario 1 – Clear Area

A 3m x 5m conventional transformer compound will require a 131m2 of the clear fire risk area. It is the most cost-effective option given the installation footprint required is available and clear of any buildings.

Scenario 2 – Fire Barrier

If space is limited and buildings are within the fire risk Zone A, a fire rated barrier can be installed, to the following specification:

- A 2-hour fire rated (FRL 120/120/120) barrier adjacent to the building,

- The vertical extent of the fire barrier is required to be 7.5m tall; and

- a minimum horizontal distance of 1.5m away from the transformer compound.

Scenario 3 – Enhanced Protection Transformer

An alternate option is to install a fire protection class of transformer, such as GSM™ transformer. AS2067 defines this as ‘less combustible liquid-insulated transformer with Enhanced Protection. The separation distance to a non-combustible surface or building for this type of transformer is 0.9m, without the need for fire rated barrier. This translates to a footprint of only 24m2 which is more than 550% less area required when compared to outdoor Scenario 1.

The differences in the type of transformer to clearance requirements and fire risk zone, as shown in Table 1.

INDOOR INSTALLATION

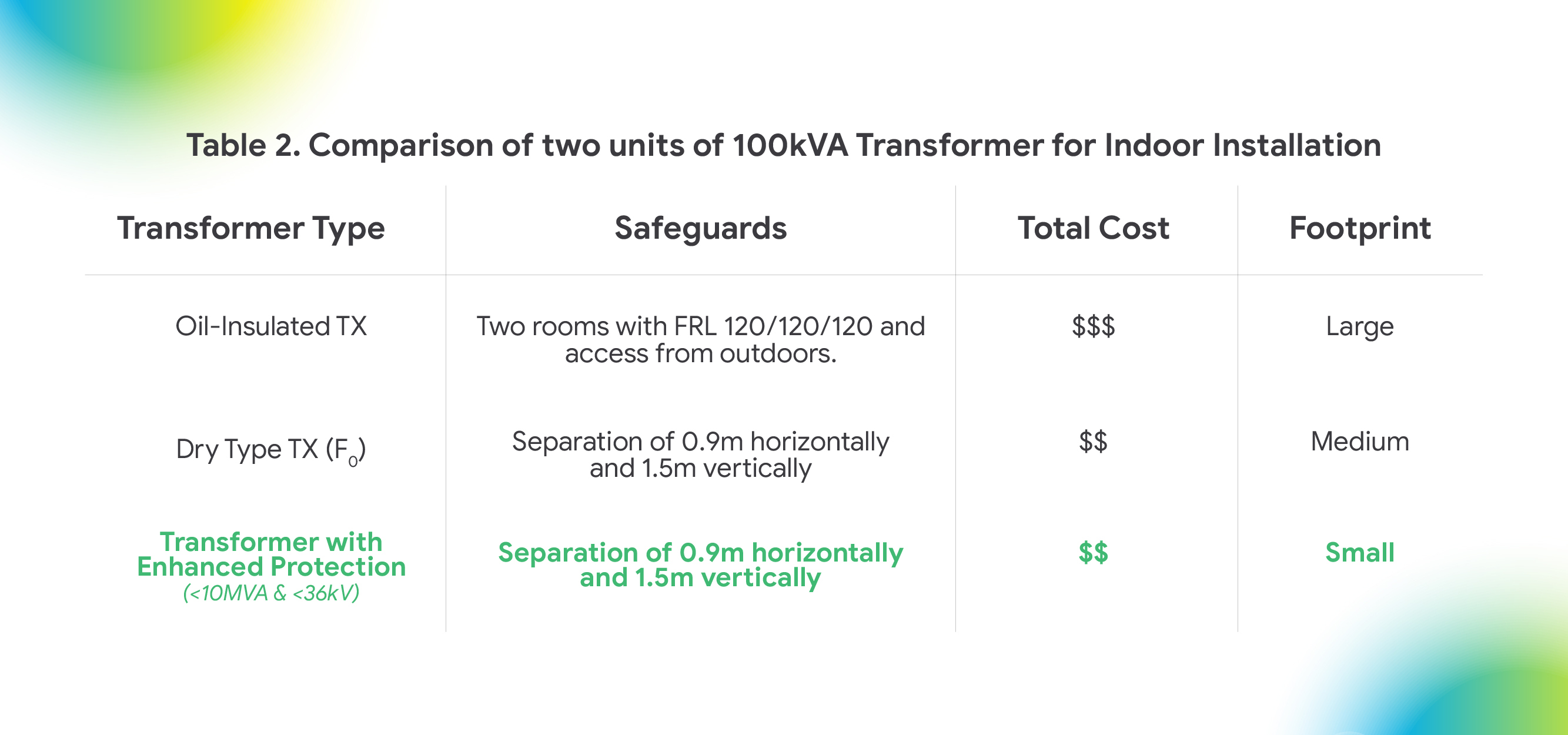

Similarly, for an indoor transformer installation, the minimum fire safeguards are defined in AS2067 and differ depending on the type of transformer installed. Using an example of two units of 1000kVA transformer, the following scenarios are outlined below.

Scenario 1 – Oil-insulated Transformer

Conventional oil-insulated transformer installed inside any building must have a 2-hour fire resistance level (FRL 120/120/120) with subdivision for each transformer. This means that the substation must be constructed with two rooms, each with access from outdoors.

Scenario 2 – Dry-type Transformer

It is a common approach in the industry to use a dry-type transformer inside buildings. This method requires a separation distance of 0.9m horizontally and 1.5m vertically between the transformer and other equipment. Dry-type enclosures are usually utilised in this scenario to prevent electrical contact, which causes the equipment footprint to be larger than an oil-insulated transformer.

Scenario 3 – Enhanced Protection Transformer

Alternatively, two transformers with Enhanced Protection can be installed inside one switchroom, with identical separation distance as scenario 2. It is recommended to provide individual liquid containment for each transformer. This approach is ideal as the footprint and Fire Risk Zone is the smallest. It also often a viable solution for transformer replacements in an older/existing building without fire rated wall.

ENHANCED FIRE PROTECTION GSM™

The Australian standards define a transformer with Enhanced Protection must protect against high energy and lower energy faults, increase tank strength, and pressure relief. It also must be certified by Factory Mutual Global.

Exnovo range of GSM™ transformers is certified by FM Global with Enhanced Protection. A key benefit of using an Enhanced Protection transformer such as GSM™ is the reduction in clearances to buildings as per AS2067. This ensures a safer operation of the asset and presents an ideal solution for energy provision where space is a premium.

For further information about our range of Transformers with Enhanced Protection, please contact EXNOVO at +61 (8) 6102 2814 or email us at contactus@xnv.com.au or visit us at xnv.com.au.

Reference

“Less or Non-Flammable Liquid Insulated Transformers”, Approval Guide, 2020. [Online]. Available: https://www.approvalguide.com/....

“Approval Standard for Less or Nonflammable Liquid-Insulated Transformers: Class Number 3990”, FM Approvals, 2018.

“Substations and high voltage installations exceeding 1 kV a.c.”, Standards Australia, 2016. [Online]. Available: https://www.standards.org.au/s...–2067-colon-2016.